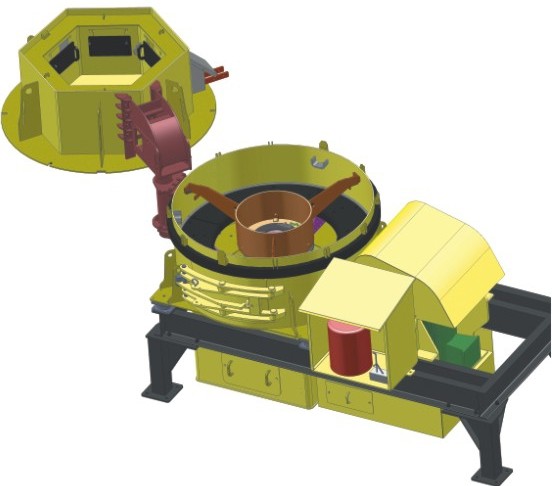

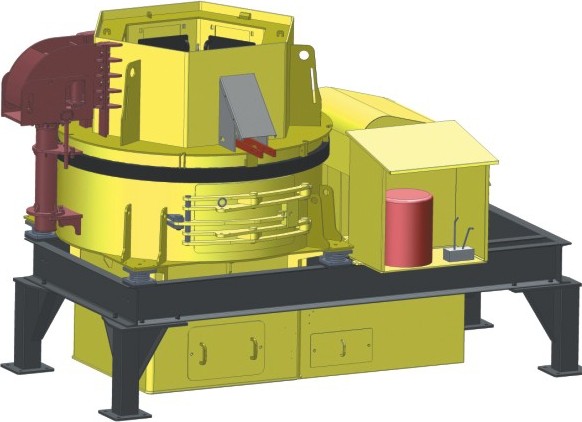

Vertical Shaft Impact Crusher

Offering Top-of-the-Line Impact Crushers

Vertical shaft impact (VSI) crusher is widely used for quaternary, tertiary, and secondary applications of crushing rock, cement clinker, quartzite, and concrete aggregate and especially for the sand making and road paving.

VSI Crusher Basic Concepts

VSI and GS series crushers feature a unique combination of rotor design, wear material, and crushing equipment design. This combination is proven to be a revolutionary in improving capacity and superior product shape quality and in reducing operating and wear costs.

VSI and GS series crushers are characterized by a unique closed-rotor design providing a higher reduction ratio with lower wear cost. The GS series crusher’s bearing seat uses a thin oil lubrication system. Its highest rotor speed is clocked at 82m/s, greatly improving the capacity of the equipment and processing efficiency. In addition, VSI and GS series crushers have been designed to minimize maintenance and improve all the adjustment operations.

VSI and GS series crushers provide unbeatable performance in secondary, tertiary, quaternary, and shape.

VSI Crusher Series

-

VSI2000

-

VSI3000

-

VSI4000

-

VSI4200

-

VSI5200

-

GS300

-

GS320

-

GS420

VSI Crusher Terminology

Setting the Rotor Speed (RPM)

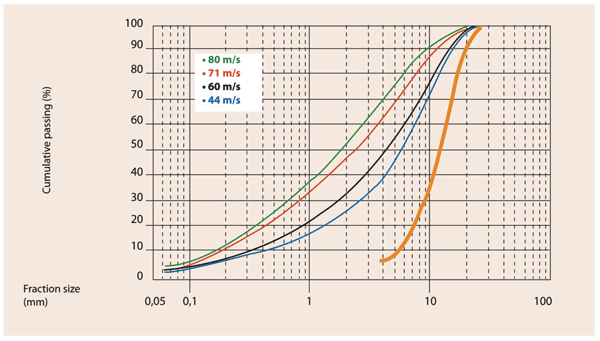

Unlike compression-based crushers, the AF VSI and GS series crushers do not have closed and open side settings (CSS and OSS) to specify what size the product will be once it has gone through the crusher. The main way to adjust the reduction ratio of the VSI and GS is by adjusting the rotor rip speed. This can be done by a variable speed drive or by changing the motor/crusher pulleys.

At a rotor tip speed of 45m/s, crushing is at its lowest, but we have a high capacity. At 82m/s, crushing is at its highest, but we have a lower capacity.

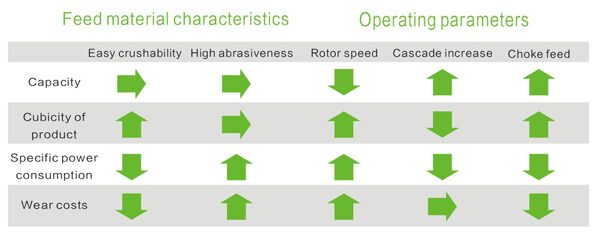

The size of the crusher product also depends on the feed size, the throughput, the crushability of the material, and whether or not the cascade feature is used. If any of these things are adjusted, it will change the grading of the product.

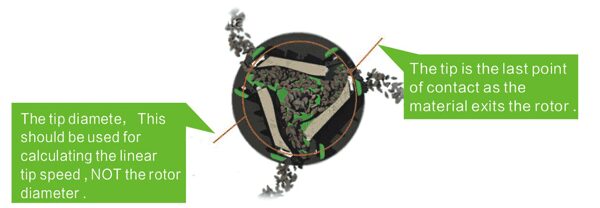

Calculating the Rotor/Tip Speed

Rotor speed is the rate in revolutions per minute (RPM) that the rotor is spinning in the crushing chamber. We calculate the rotor speed using the following formula:

Motor RPM x Motor Pulley Diameter (mm) / Crusher Pulley Diameter (mm)

Tip speed is the speed in meters per second (m/s) that the rotor tip is spinning on the outside of the rotor. We calculate the rotor tip speed using the following formula:

2 x (Rotor RPM x Pi) x Rotor Center to Tip Measurement (Tip Radius) (m) / 60

Once the speeds are calculated, it is possible to adjust the speed by changing the crusher or motor pulley.

Note: The tip diameter should be used for calculating the linear tip speed, not the rotor diameter.

Note: The tip is the last point of contact as the material exits the rotor.

Main Parts

-

3-Port Rotor

-

4-Port Rotor

VSI Crusher Features and Benefits

VSI and GS series crushers are the solution for the current and future operating conditions in which output and productivity demands are increasingly stringent. Our engineers have optimized the machine layout to maximize compactness with a single drive shaft to make the machine even stronger and more powerful without unbalancing the rotor.

A lot of effort has gone into redesigning the rotor to minimize wear while increasing crushing reduction factors and capacity. VSI and GS series crushers enable you to achieve a higher reduction rate with fewer crushing stages, lowering your capital costs and saving energy.

AF Minerals Equipment’s national reputation is based on crushing plant efficiency and quality. VSI and GS series crushers are firmly rooted in this tradition. Ongoing collaboration with many research laboratories has now made it possible to bring you state-of-the-art technical innovations in terms of the durability of wear parts (tips, liners, and rotors) and the reliability of the mechanical components used in the crushers (drive shaft, bearings, etc).

The strength of VSI and GS series crushers make them ideal for every kind of application in many different configurations. VSI and GS series crushers have demonstrated their effectiveness in many applications ranging from crushing low abrasion materials to extremely abrasive products for the industry.

The GS series vertical shaft crusher has improved bearing lubrication. It uses a thin oil lubrication system equipped with a temperature gauge for strict control bearing temperature in bearing seat, avoiding bearing damage caused by too high temperatures.

The rotor speed of the GS series vertical shaft crusher at the highest is clocked at 82m/s due to highly efficient cooling. Compared with VSI series crushers, GS series vertical shaft crushers have more capacity and lower power consumption.

Extremely modular, VSI and GS series crushers’ layouts can be in the same frame and changed without major modifications from a rock-on-rock rotor to a rock-on-iron rotor. They feature many technical benefits such as the tapered shape of the anvils making it possible to turn them when they are half worn and to boost the payload, thereby improving productivity.

The specific shape of the closed rotor reduces rotor wear and maintenance costs by increasing reduction factors.

- Rock-to-Rock Rotor

- Rock-to-Iron Rotor

- Easy to maintain with high-security level

No drastic modifications are required if, for any reason, you decide to change your VSI or GS crusher tasking. Machine design limits dust emissions by reducing and re-circulating air flows within the crusher confinement hood. The VSI and GS series crushers are all pre-equipped for fitting a wide range of dust traps.

Once set up for a specific mission, the VSI or GS series crushers do not need fine-tuning to maximize performances.

AF aftermarket network means help is always close by. If you ever have any questions or problems, we are always ready to get you operating at peak efficiency in no time.

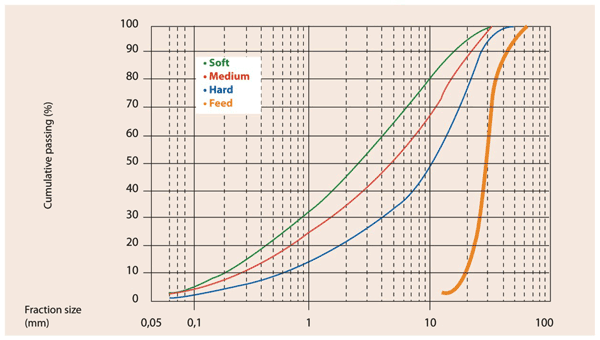

VSI Crusher Gradation Curve

The output screen analysis of vertical impact crushers varies according to different parameters, the feed-screen analysis, the feed material, and the rotor speed.

The output screen analysis may change for different rocks with the same feed-screen analysis and the same rotor speed.

If the rotor speed increases, the screen analysis will be finer.

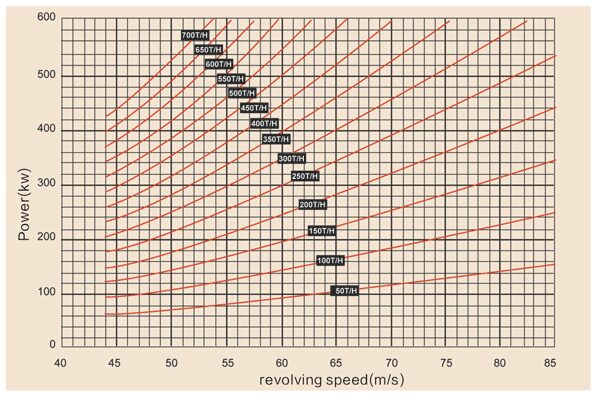

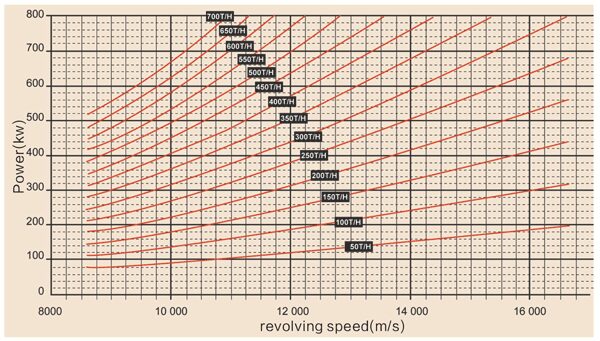

Power Requirement (Metric)

The above power requirements are only indicative

Power Requirement (Imperial)

The above power requirements are only indicative

VSI Crusher Dimensions and Technical Data

VSI Crusher Wear Parts

The wear parts for AF VSI and GS series crushers are contained both within and on the outer surfaces of the rotor. Different parts have material technology to resist either impact or abrasive wear. The selection of the correct wear parts for the application required is fundamental to ensure the desired performance. Parts must be chosen according to the feed material characteristics of abrasiveness and crushability, feed size, and rotor speed to suit the product requirements.

In using rock-on-rock VSI and GS equipment, it is essential that wear parts allow stone beds to form to prevent wear on steelwork and exposed edges of the rotor. It is important to choose materials that, under normal operating conditions, offer the best performance.

AF VSI and GS series crushers have many different wear parts inside the rotor, including:

Wear Evaluation

The wear parts that are worn the most inside the rotor are the distributor plate, rotor tips, lower wear plates, and feed tube. This happens because these parts have direct contact with the feed material at all times as it passes through the rotor.

The distributor plate is worn in two ways, by impact, as the material falls vertically into the rotor; by abrasion, as it is sent horizontally out of the rotor.

The rotor tips are the last thing to touch the feed material as it exits the rotor. It has a tungsten insert that improves wear life. We often use the life of the tips as a reference point for the other rotor wear parts.

The lower wear plates are worn more because gravity pulls the feed material down onto the bottom of the rotor as it exits.

Standard rotors will also wear the upper wear plates as the space inside the rotor is smaller than that of a deep rotor.

The feed tube is worn as it guides the feed material into the rotor opening as it comes down from the hopper.

How to Operate a VSI Crusher

The basic principle of operating a VSI crusher is to accelerate stones to break against each other in a crushing chamber.

There are a number of factors that will affect the operation

- Feed Size, Gradation, and Capacity

- Material Type

- Speed of Rotor

With a slow rotor speed, you will achieve:

With a fast rotor speed, you will achieve:

The speed and throughput of the rotor will determine the power needs for the particular application.

The Advantages of Crushing by Impact

No Residual Fracture:

If the stone is very laminated, crushing by impact will reduce the residual fracture.

The Shape of the Aggregates:

Material that is crushed using impact has a much more cubical shape than that of a material crushed using compression. This is due to the impact breaking the material along its weakest planes to give sound, solid, and cubical particles. Compression crushing produces more flaky and elongated particles that are not always acceptable for modern concrete and asphalt specifications.

The AF VSI and GS series crushing action also involves grinding as well as impact and therefore improves the shape of the final product even more.

With a VSI, the reduction ratio depends on the following factors:

- Top Feed Size

- Speed of Rotor

- Material Characteristics

Note: In an open circuit, the reduction ratio is not important as the feed grading will be changed relative to the rotor speed. In a closed circuit, the reduction ratio can be from 1 to 15.

Impact crushing causes immediate fracture with no residual stress:

This stress-free condition is very valuable to construction materials. This property is one of the reasons why impact crushing is widely used in the quarrying industry.

World of Difference

Before, during, and after the sale, you can count on the experts at AF Minerals Equipment to provide the best service and support in the world, all over the world. Whether you’re installing an entire customized system or a complete circuit or simply replacing or updating a single piece of equipment, you can count on us to help you make sure it’s the right equipment for your precise needs.

In the design stage, we look at variables such as ore characteristics and properties, physical space limitations, the size of the ore body, and even your financial situation just to name a few. Once you make your purchase, you’ll be linked to AF’s online computerized parts availability system, giving you immediate access to the right parts in stock. We ensure to deliver them to you promptly.

If you have questions, a trained service analyst is always standing by, over the phone or in person, ready to analyze your needs and recommend a complete, long-term, and cost-effective solution.

![Single Motor [ Click image to full view ]](https://afmineral.com/wp-content/uploads/bb-plugin/cache/Single-Motor-square.png)

![Single motor technical data [ Click image to full view ]](https://afmineral.com/wp-content/uploads/bb-plugin/cache/Single-motor-technical-data-square.png)

![Single motor technical data--high speed [ Click image to full view ]](https://afmineral.com/wp-content/uploads/bb-plugin/cache/Single-motor-technical-data-high-speed-square.png)

![Dual motor [ Click image to full view ]](https://afmineral.com/wp-content/uploads/bb-plugin/cache/Dual-motor-square.png)

![Dual motor technical data_ [ Click image to full view ]](https://afmineral.com/wp-content/uploads/bb-plugin/cache/Dual-motor-technical-data_-square.png)

![Dual motor technical data--high speed [ Click image to full view ]](https://afmineral.com/wp-content/uploads/bb-plugin/cache/Dual-motor-technical-data-high-speed-square.png)

![Particle before crushing [ Click image to full view ]](https://afmineral.com/wp-content/uploads/bb-plugin/cache/Particle-before-crushing-square.jpg)

![Particle after crushing by compression [ Click image to full view ]](https://afmineral.com/wp-content/uploads/bb-plugin/cache/Particle-after-crushing-by-compression-square.jpg)

![[ Click image to full view ]](https://afmineral.com/wp-content/uploads/bb-plugin/cache/Particle-after-crushing-by-impact-square.jpg)